HGBM-1 Garlic Brusher Machine

Garlic Brusher Machine by HUAYO AGRO can clean garlic bulb with 5 brushes, brush the dirt and soil off garlic

HGBM-1 Garlic Brusher Machine by HUAYO AGRO will clean whole Garlic bulb with brushes effectively. It can process 1-2 tons of Garlic in one hour, and work for Commercial Garlic Farm.

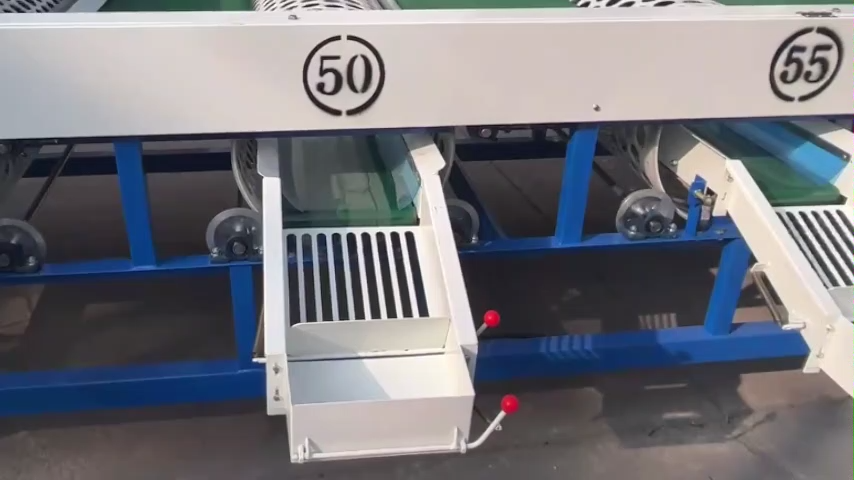

The Garlic Brushing Machine can clean garlic bulbs with 5 soft brushes and grade them with 3 sizes automaticlly. Firstly, It will clean the soil and external brown peals of garlic without damage the garlic. Secondly, the Grading Machine will size the garlic head precisely to 3 sizes, like 45mm, 50mm, 55mm etc. We can customize the Grading sizes for you .

The Garlic Bulb Brushing line includes three parts: Roller Conveyor, Garlic Brush cleaning Machine and Garlic Bulb Grader.

Firstly, Roller Conveyor transfer Garlic Bulb uniformly to the brushing machine. and then Secondly, the 2m wide Brushing Machine remove efficiently the soil and the external brown peals. after that, the cleaned garlic bulb will be graded to 3 sizes automaticlly.

Therefore, The Garlic Cleaning Machine is also called Garlic dry cleaning sorting machine, Garlic Brushing Machine, and Garlic cleaning and grading machine.

Technical Parameter

| Name | Garlic Brusher Machine |

| Model | HGBM-1 |

| Capacity | 1-2 t/h |

| Outsize | 1.5*1*1.2 m |

| Weight | 500 kg |

| Garlic Grading sizes | 3 |

Working video

The working process

First, pour the garlic into the Garlic Conveyor, and then lift them evenly through the rollers to the brush machine to remove the soil and dirt skin.

Second, The Garlic Brushing Machine will clean the Garlic with strong Brushes. They rotate with high speed and take off the soil and dirt skin of garlic head. Before the Clean garlic go to the Garlic Grader, the fan will blow away the dirt skin .

Thirdly, When the garlic enters the grader, the smaller garlic will fall in and out of the hopper through the round hole on the drum , while the larger garlic will roll to the next one under the rotation of the previous drum. Use a drum with a larger hole for grading and discharging.

Pictures

Cleaning Garlic before selling is an essential step . Cleaned Garlic bulbs look more fresh and appealing. Removing soil and loose outer layers creates a neat and uniform apperance, which is crucial for retail and export markets. What’s more, Cleaning helps identify and remove damaged or diseased bulbs, maintaining high-quality standards. More importantly, Removing external moisture and soil reduces the risk of fungal growth or rotting.

The Soft Brushes remove the soil, external dry peals and any other parts without damage the garlic bulbs.

The Grading Machine have designed holes. The Garlic head will drop from the right holes and unload from the outlets.

There is red handle at the outlets to control the unloading. 60mm Garlic come out from the 60 outlets.

HGBM-2 Garlic Cleaning and Sorting Machine can sort garlic with 4 sizes

1-HGBM-3 Garlic Cleaning and Sorting Machine

2-HGBS-3 Garlic Seed Splitting and Sorting Machine

Garlic Bulb Mesh Bag Packing Machine

HUAYO GARLIC – Your Trusted Expert in Garlic Machinery!

HUAYO GARLIC is specialized in Best Garlic Machine Design and Manufacturing since 2015. We aim to mechanize Garlic growing machines and Garlic Processing Machine for Garlic Growers and Garlic Process Companys.

At present, we manufacture a series of Garlic machines from planting to harvesting, cleaning , grading, and garlic process machines for Commercial Garlic Farm, and Small Family Garlic Farms. which are Garlic Splitter and Clove Sorter, Garlic Planter, Garlic Harvester, Garlic Root and Stem Cutter, Garlic Brush Cleaning Machine, Garlic Bulb Grader, Garlic Powder and Granulates Processing Machines, Garlic Peeling Machines, Black Garlic Machines.

Welcome to contact us for customize the black garlic machines you need.